- PNP | DỰ ÁN GOODWILL VŨNG TÀU: ĐỘT PHÁ THẨM MỸ VỚI GIẢI PHÁP PANEL GÓC THẾ HỆ MỚI 27/01/2026

- PNP | TRỞ THÀNH ĐỐI TÁC VÀNG - SỰ GHI NHẬN TỪ DỰ ÁN THỰC TẾ 14/01/2026

- PNP | AMKOR VIỆT NAM VÀ TIÊU CHUẨN BAO CHE CHO NHÀ MÁY CÔNG NGHỆ CAO 05/01/2026

- PNP | PHƯƠNG NAM PANEL CHÚC MỪNG NECS KHÁNH THÀNH KHO LẠNH & KỶ NIỆM 5 NĂM THÀNH LẬP 12/12/2025

- PNP | SAO MAI FACTORY - CULTIVATING THE VALUE OF VIETNAMESE AGRICULTURAL PRODUCTS 15/10/2025

- PNP | TREND POWER FACTORY PROJECT – THE GROWTH POTENTIAL OF BATTERY AND ACCUMULATOR MANUFACTURING PLANTS 29/07/2025

News

PNP | MINH PHÁT – A GREEN LEAP FOR CÀ MAU’S SEAFOOD INDUSTRY

Based on a circular economy and carbon balance model, the Minh Phát Project in Cà Mau, initiated by Minh Phu Seafood Corporation, marks a significant step toward innovation and sustainable development. From shrimp farming to processing, every stage of the Minh Phu Cà Mau operation is optimized to maximize value, minimize waste, and reduce greenhouse gas emissions. Through a circular economic strategy, organic wastewater is reused as bio-fertilizer, while renewable energy sources like solar power help balance carbon emissions throughout the entire production cycle.

With an impressive processing capacity of up to 18,000 tons of finished shrimp annually, the Minh Phát Cà Mau Project not only boosts export turnover but also strengthens the global competitiveness of Vietnam’s seafood industry. The adoption of a closed-loop production process that meets HACCP, BRC, and ASC standards ensures Minh Phu’s shrimp products satisfy the strict requirements of European, American, and Japanese markets. Each exported batch is strictly controlled — from raw shrimp quality to packaging and cold storage — guaranteeing freshness and food safety.

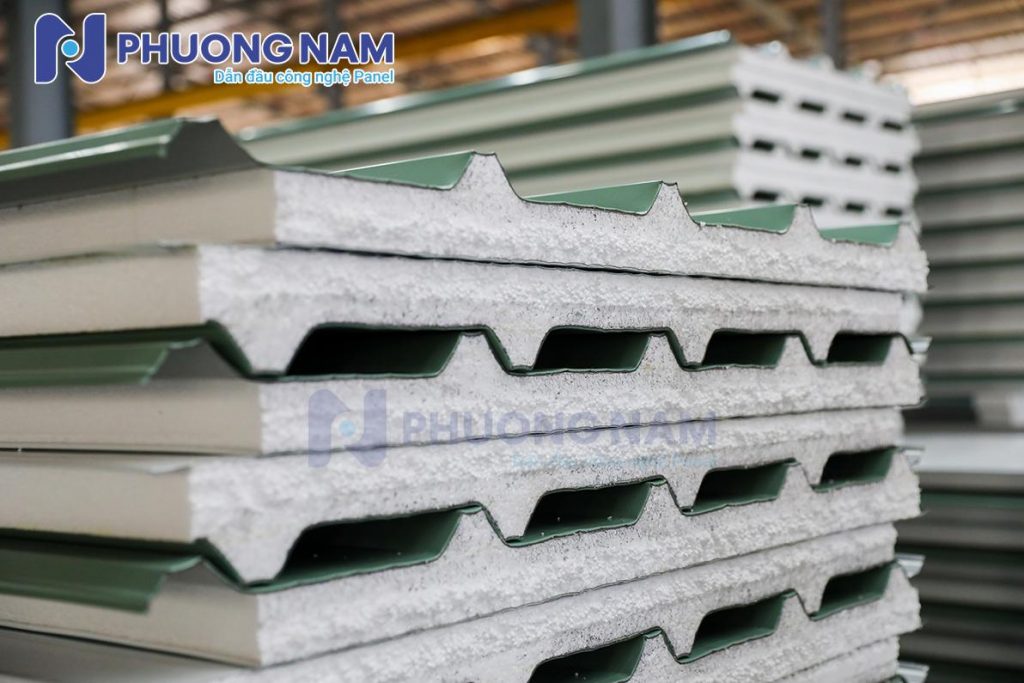

A key highlight of this project is the installation of over 40,000 m² of Procy Panel PIR — a cutting-edge, EI60 fire-resistant and environmentally friendly insulation solution. In Cà Mau’s coastal climate, with high humidity and year-round heat, Procy Panel PIR demonstrates outstanding thermal insulation, maintaining stable temperatures in shrimp processing areas and reducing energy consumption for cooling systems. The PIR (Polyisocyanurate) core enhances insulation efficiency by up to 30% compared to conventional materials, while the EI60 fire-resistance rating ensures top-level safety, helping prevent fire spread and protecting both assets and personnel.

Importantly, Procy Panel PIR is 100% CFC-free, environmentally friendly, and contributes to lowering CO₂ emissions, fully aligning with the carbon neutrality goals of the Minh Phát Project. Its corrosion-resistant, salt-acid-proof pre-painted steel surface extends the building’s lifespan and reduces maintenance costs. The quick installation process, with pre-sized panels, allows Minh Phu to save time, labor costs, and accelerate the completion of the shrimp processing plant.

Beyond technical and material advancements, the success of the Minh Phát Cà Mau Project stems from the investor’s strong commitment to environmental protection and community welfare. Minh Phu provides training and skill transfer to local workers, creating hundreds of stable jobs. A biological wastewater treatment system compliant with QCVN 62-MT:2016/BTNMT standards, combined with renewable energy, helps ease pressure on the national power grid and reduce carbon emissions. Moreover, Minh Phu’s initiatives — such as building schools, cultural centers, and offering scholarships to fishermen's children — further emphasize their deep social responsibility.

Minh Phát Project in Cà Mau is not just a breakthrough in seafood processing — it is a powerful testament to the vision of greening Vietnam’s industry. With over 40,000 m² of Procy Panel PIR installed across processing areas, cold storage, and control rooms, the Minh Phát facility operates with high efficiency, energy savings, and minimal maintenance costs. Additionally, Procy Panel PIR helps control humidity, reduce noise, and create a comfortable working environment for employees.

If you are an investor, engineer, or contractor seeking a cladding, insulation, and fire-safety solution for industrial projects, cold storage, or food processing plants, Procy Panel PIR is your top choice. Contact us today for technical consultation, competitive pricing, and let’s work together to build sustainable, green projects for the future.