- THÔNG BÁO NGHỈ TẾT NGUYÊN ĐÁN 2026 12/02/2026

- LỄ KÝ KẾT HỢP TÁC CHIẾN LƯỢC PHƯƠNG NAM PANEL × DECOFI : XÂY DỰNG TƯƠNG LAI BẰNG GIẢI PHÁP CÔNG TRÌNH ĐỒNG BỘ 05/02/2026

- PHƯƠNG NAM PANEL TẠI VSCF 2025 - DẤU ẤN DOANH NGHIỆP VẬT LIỆU XANH TIÊU BIỂU 26/12/2025

- PNP ĐƯỢC VINH DANH DOANH NGHIỆP XANH TP.HCM 2025: HÀNH TRÌNH KHÔNG NGỪNG NGHỈ 23/12/2025

- PNP | PHƯƠNG NAM PANEL TẠI GRECO 2025 – DẤU ẤN NGÀNH VẬT LIỆU XANH VIỆT NAM TRÊN HÀNH TRÌNH VƯƠN TẦM QUỐC TẾ 28/11/2025

- PNP | PHUONG NAM PANEL OFFICIALLY ACHIEVES UL GREENGUARD AND UL GREENGUARD GOLD CERTIFICATIONS 10/11/2025

News

PNP | NEW WEAPON OF PHUONG NAM PANEL FOR HIGH-TECH FACTORY IN FIRE SAFETY

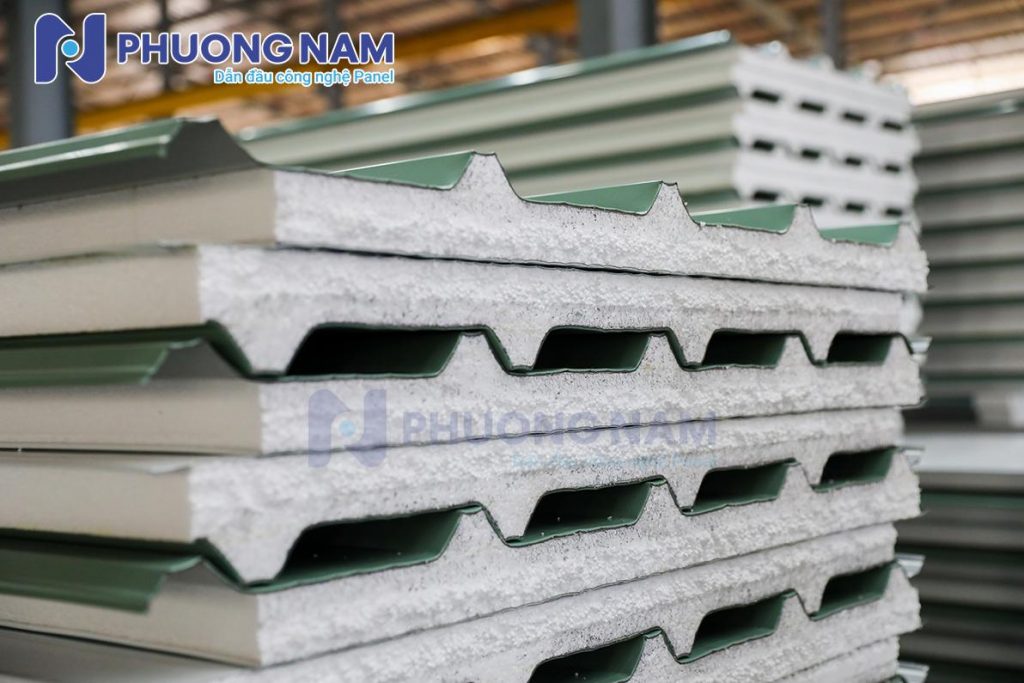

El150 - thickness 125mm - warranty 25 years: these are not ordinary indicators but the result of thousands of hours of research and development of Phuong Nam Panel to create T*ROCK PANEL.

The latest high-end panel product line in Phuong Nam Panel's ecosystem affirms the position of "Technology Benchmark" when possessing perfect technical indicators to help solve difficult problems in fire safety and improve aesthetic quality in factory construction, factory.

How to build high-tech factories and factories with the lowest investment cost and still be effective. Covering items such as inner walls, outer walls, partitions and roofs with soundproofing, heat insulation, fire resistance ... with a project scale of tens of hectares in a few months, but still meeting the strict requirements of technical standards, construction progress in unusually sunny and rainy weather, and soil foundations prone to subsidence in some regions of Vietnam.

How to maintain the performance of the project, more economical when going into operation. In hot and humid seasonal weather conditions, electricity costs and maintenance costs must be minimized.

With soundproofing panel products, Phuong Nam Panel has really promoted to create a revolution in the field of building materials with green technology optimization products. As a manufacturer of lightweight materials, green materials with the most modern technology today, Phuong Nam Panel has proven its ability to lead the market, with the launch of T*ROCK high-end panel products.

T*ROCK panels are the pioneer panels in Vietnam applying E+ TECHNIK technology to meet fire resistance standards and strict heat retention. With 5 features associated with 5 preeminent technologies: Fire Safe - Stabi - Accu - Dura - Eco, T*ROCK is considered a great step, not only improving the efficiency and aesthetics of the project but also optimally saving time, human resources and costs for investors and construction contractors.

Fire Safe technology in T*ROCK integrates Conrock flame retardant mineral wool core from reputable Danish supplier Rockwool, high-quality Australian Bluescope steel to ensure the most optimal fire resistance and insulation performance. The product meets the most stringent certificates EN13501-1/A2-s1, d0 and certified by the Fire Protection Department of the Ministry of Public Security, especially T*ROCK is also a rare product on the market that meets the high fire protection standard EI150 (time 150 minutes) with a panel thickness of 125mm.

Phuong Nam Panel pays great attention to production input materials, product quality is said to be a breakthrough improvement of the experience of Phuong Nam engineers and foreign experts in Panel production technology.

T*ROCK PANEL has overcome all inadequacies in the production of the panel industry. The technology applies achievements against deformation and metal fracture in precision mechanics, helping T*ROCK panels have a very tight mount, increasing bearing. The spray system with the glue mixing spray ratio automatically adjusts to the humidity and temperature when operating, evenly enhancing the adhesion between the Rockwool core and the two sides of the solid protective corrugated iron. maintain performance, improve longevity, suitable for all natural conditions and all architectural designs.

Not only meeting fire safety standards, T*rock meets green, environmentally friendly standards and protects public health.

According to engineers' calculations, the insulation index of a 50mm thick T*ROCK panel is equivalent to the insulation index of a 200mm thick masonry wall. Lighter weight, faster erection construction, half the time it takes to build bowls and paint baits, and significantly reduce the number of erection workers. Together with the construction of a covering wall, with panels, workers only need to connect and assemble panels, either manually, or by specialized shooters. While building rough brick walls, it is necessary to plaster, paint multi-layer baits with surface aesthetics ... Not to mention the use of Panel instead of traditional materials, the contractor will avoid cracks, moss stains, even subsidence, very dangerous both during construction or when the project has been put into use.

Benefits, T*ROCK panels are considered to bring very high benefits to users from contractors to investors, operators or value operators of the project.

Sandwich Panel materials erected for buildings are essential, creating sustainable development, environmental protection and human health safety. Industrial or civil works constructed with environmentally friendly materials (green materials) are an inevitable trend in the world. The presence of T*ROCK, as well as the increase in capacity of Southern panel factories, is a signal that this solution has been and will be an indispensable choice of green buildings at present and in the future.

For more information about T*ROCK PANEL and Phuong Nam Panel, please visit: Phuong Nam - Leading sandwich panel quality (phuongnampanel.com)

SOUTHERN PANEL

https://www.phuongnampanel.com

https://www.facebook.com/congtytnhhcachamcachnhietphuongnam

hi@panelphuongnam.com

028.3590.1968 - 0221.3571.599 (North Office)

T*ROCK PANEL Rockwool EI150, panel thickness 125mm

Fire Safe – Perfect fire resistance, optimal insulation

Stabi – Modern, multidimensional, sustainable core structure

Accu – Standard tight-fitting mount, synchronous accessories

Dura – Rugged warranty up to 25 years

Eco – Environmentally friendly, protecting public health