- PNP | DỰ ÁN GOODWILL VŨNG TÀU: ĐỘT PHÁ THẨM MỸ VỚI GIẢI PHÁP PANEL GÓC THẾ HỆ MỚI 27/01/2026

- PNP | TRỞ THÀNH ĐỐI TÁC VÀNG - SỰ GHI NHẬN TỪ DỰ ÁN THỰC TẾ 14/01/2026

- PNP | AMKOR VIỆT NAM VÀ TIÊU CHUẨN BAO CHE CHO NHÀ MÁY CÔNG NGHỆ CAO 05/01/2026

- PNP | PHƯƠNG NAM PANEL CHÚC MỪNG NECS KHÁNH THÀNH KHO LẠNH & KỶ NIỆM 5 NĂM THÀNH LẬP 12/12/2025

- PNP | SAO MAI FACTORY - CULTIVATING THE VALUE OF VIETNAMESE AGRICULTURAL PRODUCTS 15/10/2025

- PNP | TREND POWER FACTORY PROJECT – THE GROWTH POTENTIAL OF BATTERY AND ACCUMULATOR MANUFACTURING PLANTS 29/07/2025

News

How to have a perfect cold-storage?

Installation of a cold-storage will become simple based on experience and engineering of construction. Also, a perfect cold-storage needs multi factors to be able to well operate. Be with Phuong Nam to discover such factors via following article.

What is a perfect cold-storage like?

Cold-storage is a construction projects with multi-applications such as preserving seafood, farm products, pharmaceutical, vaccines, etc. Although it is classified into many kinds, they are all similarly constructed. Design of a perfect cold-storage comprises of 2 main parts of an insulating system and a cooling system.

Insulating system

This is the collection of details functioning to keep temperature inside always stable and completely separated from ambient temperature. Generally, the insulating system of a cold-storage include following components:

-

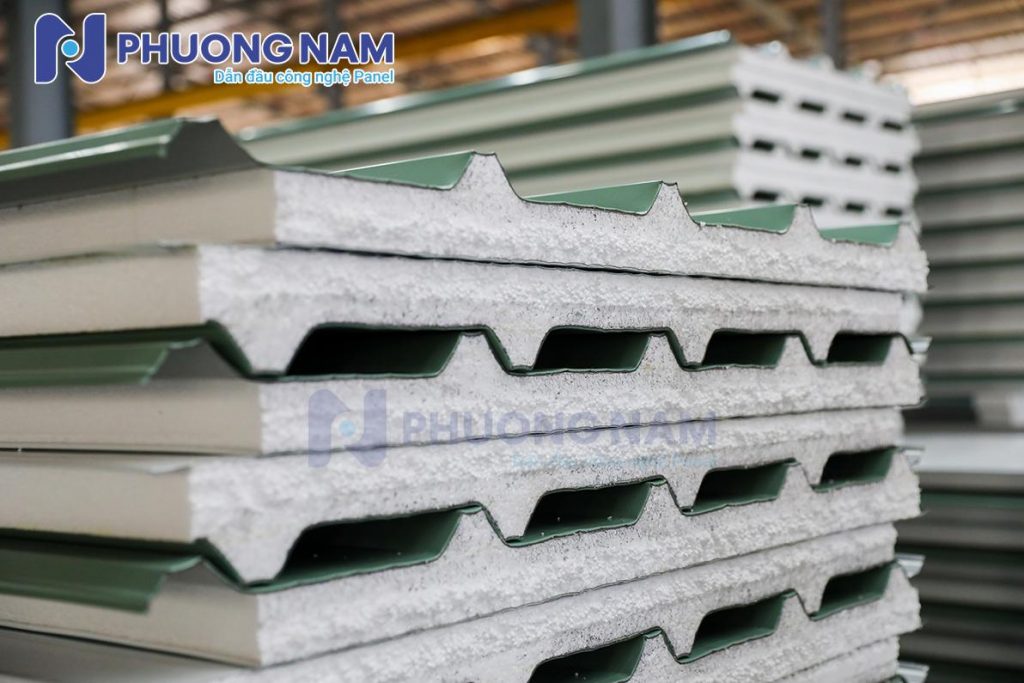

Housing: built with insulating, soundproof and fire resistant sandwich panels. Sandwich panel of cold-storages must have structure, quality and function suitable with them.

- Door: This component is required quality similar to the housing plus high flexibility for the convenience of users. Generally, the door needs rigid frame, stainless steel hinge and handle, etc. and other factors.

Cooling system

This is the part responsible for temperature suitable to the required preservation temperature.

+ Door: Depending on each kind of goods, food, etc. each cold-storage will have a different temperature. Cooling system of a cold-storage will have following details:

- Compressor: It compresses refrigerant, classified into following kinds: coil, piston, screw, etc. Depending on the kind of compressed air engine and volume of a cold-storage, it will be different design.

- Evaporator: Installed inside. This is an important part of a cold-storages to properly adjust temperature. It includes details such as centrifugal fan, thermistor, fin spacing, etc. Both compressor and evaporator are most imported from overseas.

Cubicle

It is considered as “brain” of cold-storage, having function of control and adjust

+ Door: Accordingly, the cubicle will coordinate with compressor and evaporator to adjust stably temperature according to pre-set parameters.

Now, cubicles of many brands are more “smart”. They are installed in the parts signaling troubles of device. Even, it can alarm by signaling to phone of the user

All said above components need to meet strict requirements from cold-storage. Since they are generally considered as an “apparatus”. If only one component malfunctions, the whole cold-storage will ineffectively operate resulting in loss of energy, affecting quality of the preserved goods. So, the materials, machinery to be installed must be thoroughly selected and studied.

A cold-storage is formed from quality specialized materials and equipment

Which are materials for erection of a perfect cold-storage?

Thanks to its features of light weight, soundproof, insulating, high durable, quick construction, optimal cost, etc. panel is the material that is the most commonly applied in construction of a cold-storage now a day.

However, sandwich panel market has diverse types, materials and functions. This requires customers to thoroughly study about sandwich panel for their cold-storage so that the projects is constructed with the most suitable material.

Generally, panel is suitable to construction cold-storage that meets following criteria:

- Surface is flat, smooth, bright color, rather thick for keeping temperature of cold-storages.

- The coating steel is manufactured with high-technology, rather thick and corrosion resistant and good vibration resistance.

- Panel foam core for cold-storage has thick density, free from air bubble, absolutely insulating.

- Tight clamping of panel prevent bacteria, moulds from depositing.

Referring quality sandwich panel now, it can be mentioned the product lines of Phuong Nam Soundproof, insulating Company. Thanks to modern European technology production line, Phuong Nam panel is diverse in types, perfectly meet all projects not only cold-storages but also factory, clean room, warehouse, etc.

Selection of suitable sandwich panel will bring about efficiency for installation of cold-storage

Important requirements when construction of a perfect cold-stage

Materials and components are not enough to institute a perfect cold-storage. The projects also need important requirements for construction of an effective cold-storage.

Ground of a cold-storage must be treated to avoid settlement, and require tilt within standard level.

- For heat dissipation pipe: The pipe system must be studied and properly arranged to ensure the ground surface is flat, avoid ice forming.

- Insulating panel for cold-storages needs to be properly manufactured to the projects design. During transportation, it must be ensured safety, no deformation and no damages.

- Cold-storage must be checked before putting into operation and periodically maintained to early detect any troubles. Then prompt measures are worked out to restore or increase its operation efficiency.

Cold-storage needs to be constructed under high-technique and quality materials

Installation of a cold-storage requires thoroughness in technique and quality of its components. If you are looking for a suitable sandwich panel for construction of a cold-storage, Phuong Nam is the first-choice for you. For details of the product, access phuongnampanel.com or hotline (028) 3590 1968 for being consulted free of charge